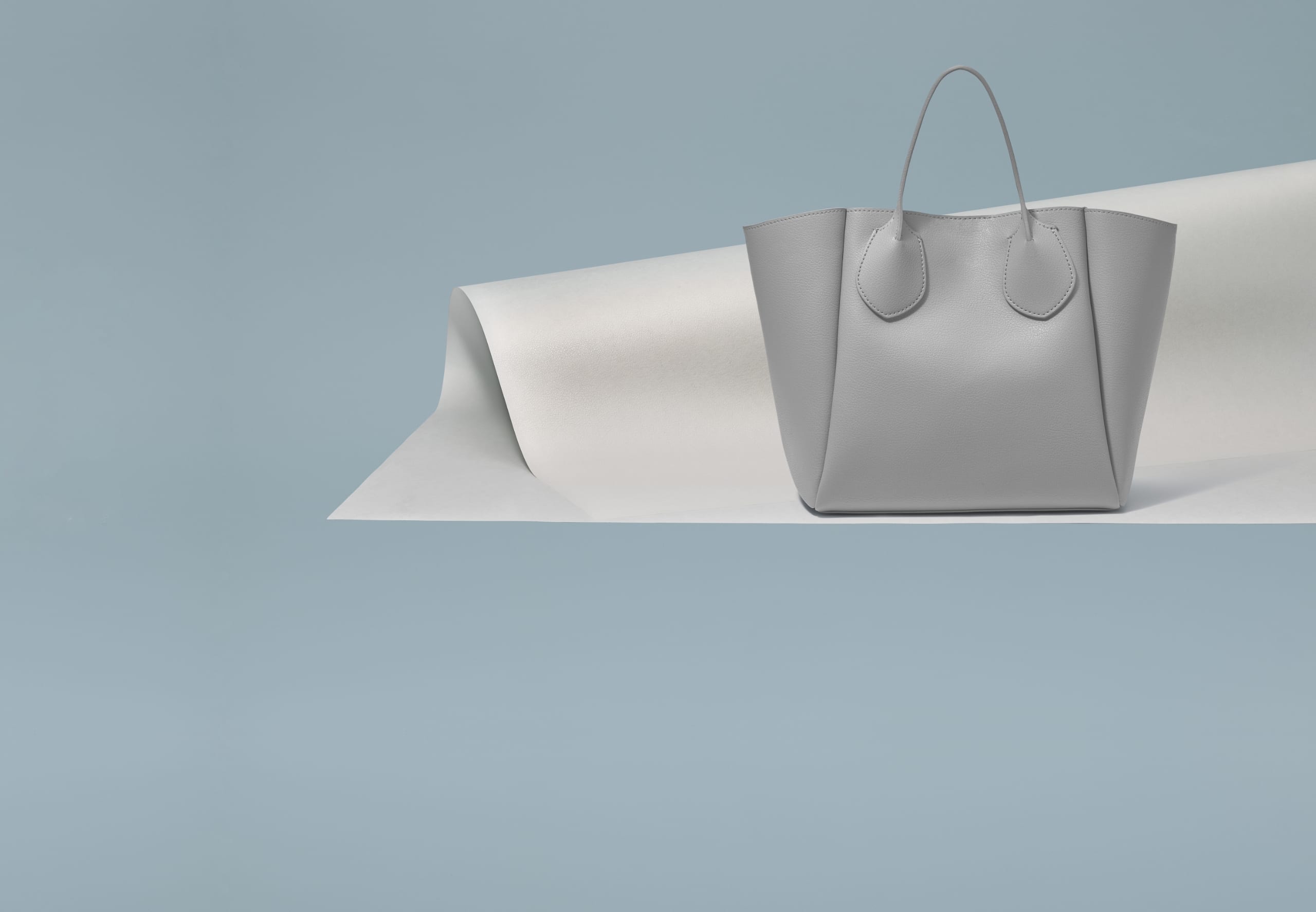

Lintec Casting paper, used in the process of synthetic leather, was first developed in Japan in 1964. With our expertise accumulated in their field for nearly 50 years, Lintec has been continuously striving to respond to the needs of the times by developing a wide variety of high quality Casting papers.

Casting paper is used in the making of synthetic leather creating a full range of excellent embossing patterns.

Trusted

Quality

LINTEC is a leading Japanese manufacturer of release liners that protect the adhesive side of various adhesive products. LINTEC also provides casting papers and other items used in the manufacturing processes of synthetic leather and carbon-composite products.

Overseas

Network

Our products have achieved sales in many countries around the world. Our distributor agents in each region are close to our customers, to facilitate sales and technical support, and having local inventory allows quick deliveries.

Diverse

Needs

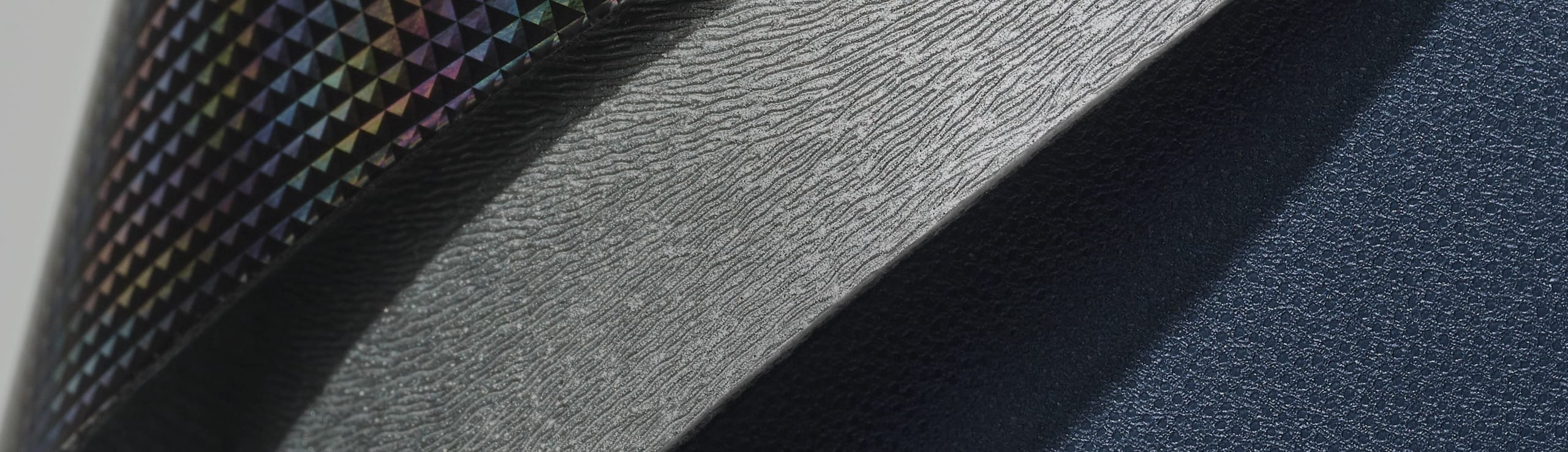

Our factories are fully equipped with laminating, coating, and embossing machines, so we can handle everything from the release treatment to the embossing process—essentially, the entire production process—in-house. We can leverage these capabilities to not only develop embossing designs, but also to flexibly and thoroughly meet our customers’ needs, such as by adjusting the release strength (ease of peeling), gloss level, and other properties.

01

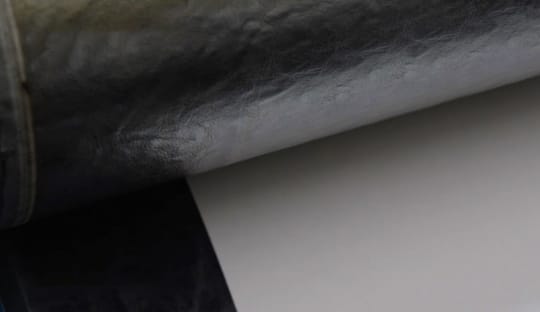

The following two release types are available. The laminate type has a polyolefin film laminated on the surface of the paper, while the coating type is coated with silicone or a special resin.

The laminate type is suited for manufacturing synthetic leather with polyurethane resin.

The casting paper itself is very durable and can be used repeatedly.

The coating type is ideal for PVC resin cast films. It is available with various gloss levels, including enamel and matte papers. The casting paper itself offers excellent heat and abrasion resistance.

Embossing rolls are used to form a textured pattern on paper supplied with a release layer, to make casting papers for synthetic leather. LINTEC offers a lineup of more than 100 different patterns to meet a wide range of customer needs, from apparel to automotive uses.

02

First, customers coat PU or other resin on casting paper, and then apply adhesive with laminating backing and peel the casting paper off after drying. The casting paper must of course allow for pattern designs, but must also have adequate release properties and be durable under repeated use.

We offer various grades of casting paper to suit our customers’ uses and product conditions.

For PU usage, we recommend EV130TPD and LXD types or PXDH for high temperature ranges, while for PVC, the VX type should be used. We recommend ENPLUS type for customers who want a high gloss.

LINTEC offers two lines of products, which are produced at either the Komatsushima factory (Japan) or at the Suzhou factory (China).

Products manufactured at the Komatsushima factory are in the “R Series,” while those made at the Suzhou factory are in the “ZR Series.”

*There are some exceptions, due to transfers of production. Please check the product page for the latest information.